I love the Internet, don’t you?!

Not only can you find INSTANTLY information on whatever your muse is wooing you towards, you can truly, if you want, get educated on a myriad of interests, no matter how offbeat or eccentric.

Take today’s post, for example: “What is a Partscaster??” is a question I had never asked until just a couple years ago.

But after some rampant Googling, a little G.A.S.-y drooling, and ramping up the ol’ studio budget, I was led to where I am today – being the proud owner of a one-of-a-kind Strat guitar that I really dig.

If you’ve never heard the term “Partscaster” before, or you’ve stumbled upon the term but want more info on it… cool. You’re in the right place to expand your brain AND your tonal palette!

Frankenstein LIVES!!

In a nutshell, a Partscaster is any guitar put together with parts, rather than one that came stock, all in one piece, from a guitar manufacturer.

The majority of players, when they want a new guitar, just go to a nearby music store and play what’s on the wall, questing for that “Holy Grail” of tone that is unique to their ears alone.

But those guitars have one sound, predetermined by the company that makes them. All models tend to sound the same. That’s what the company, and usually the consumer too, wants. It’s dependability. It’s quality control. It’s consistency.

But, if you’re like me, the sound of stock guitars is a little constricting after a while. There comes a time when you want a sound that’s unique – one that you can’t pick off the wall at Guitar Center.

It’s like Frankenstein’s monster: a creature consisting of disparate parts, from varied corpses and lab-harvested organs.

Unforgettable, right?? A lot of Partscaster are just as striking and attention-getting.

When you want your OWN brand of electric lightning, throw the switch on a Partscaster!

“LIFE! DO YOU HEAR ME? GIVE MY CREATION… LIFE!!”

She’s Got the Look!

One of the best reasons to build your own guitar creation is that you can put together combinations of wood, electronics and hardware that, to YOU, look the best you’ve ever seen.

Heck, some build one without even caring how it sounds – they just know it’s going to be sweet eye candy for their adoring audiences everywhere they go!

Want a Telecaster that has creme binding on the front AND the back?? No problemo.

Like your Strat Alder wood body, but wish it had gold pickups instead of chrome?? A simple swap and Bob’s your uncle.

Happen to play on a Pau Ferro wood fretboard and now want all your guitars to have that kind of neck??! Let the postman deliver your dream to your door!

We all have different ideas of what a “gorgeous guitar” looks like… and that’s okay. To each our own, right?!

Crafting your own Partscaster go to be particular about every detail, such that, to you, it looks absolutely… fantastic!!

Mod vs. Caster

So what’s the difference between “mod”-ing your guitar and building a Partscaster??

Well, it kinda depends on who you ask. There are divergent opinions all over the internet.

There does seem to be a slight consensus though, and that is if you’re changing any of the WOOD elements on your guitar, then it’s becoming a Partscaster.

If you’re only swapping out electronics or hardware, most consider that a simple “mod“. This kind of change-up won’t alter how your guitar feels, or resonates, much at all. It’ll just affect tone.

If you alter the wood in your guitar though, especially the body, you’ll notice a BIG difference in feel, and sustain.

Nomenclature aside, what really matters is do you want to make your guitar distinctly your own or not? If so, changing it up with parts from another company might just rev up your ride, yo!

Why “-caster”??

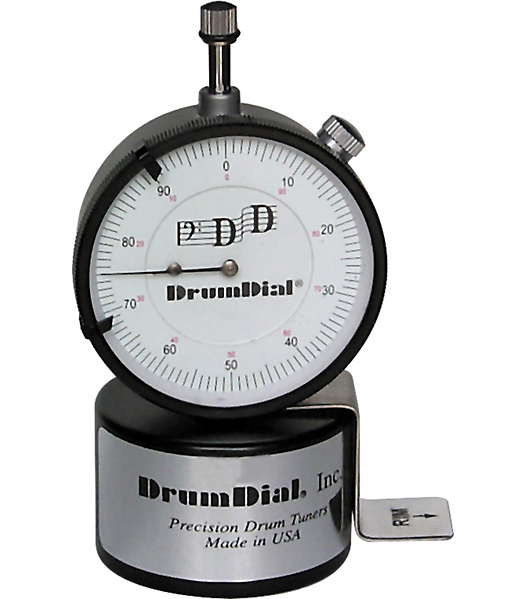

If constructing guitars were easy, then everybody would do it. But it does rather take some skill and precision to get it right…

… if you want the intonation not to suck!

Most home-grown guitars tend to be Fender Stratocaster or Telecaster styles. Is there a reason??

Yes, and it comes down to the fact that not everybody is a carpenter or luthier! Some guitars are easier to assemble than others.

Best example? Strats and Teles. They’re the easiest guitars to change necks on since they’re bolted on. It’s much harder to swap out a “set neck” that you find on a Gibson SG or LP style guitar.

The Fender styles cut you more slack; they’re not so finicky, like some other guitars with complex engineering and fitting that demand you go to Guitar Design school just to know how to set the neck properly.

Not that there even IS something called “Guitar Design School”. But there SHOULD be. Lol

Regardless, Fender has got to love it that they get free advertising whenever somebody puts their own guitar together. We don’t think of Gibson, after all, when we hear the term “Partscaster”.

And I’ve never heard anyone yet say they want to build a “PartsPaul”. 😉

But is it CHEAPER??

Yes!!

And no!

Here’s why: because the choosing of supplies for your Partscaster is totally up to you, the budget can from “very cheap” to “vastly expensive”! It’s your call.

Want to swap out your pickups? Well then, you could buy THIS HUMBUCKER for around fifty bucks.

Or, instead, invest in THIS HUMBUCKER, which is, uh… a bit more, shall we say. 😮

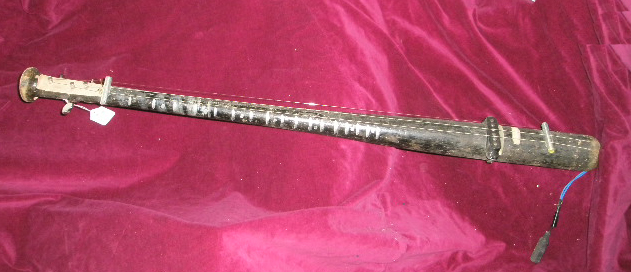

Or what about guitar necks?? There’s THIS NECK, which won’t drain your funds much at all.

But there’s also THIS NECK, which most certainly will!!

So you can see, the budget for a Partscaster can be pretty much anywhere you want it to be. Choose the total based on your own budget, and order away.

If it’s your first time trying this though, you might want to keep the cost down.

Ya know… in case you screw it up ROYALLY!! Lol

Warranty?? We Don’t Need no Stinkin’ Warranty!

It might go without saying, but I do have to mention that if you put your own guitar together, there’s no warranty, no back-up plan, no service department it’s going to have your back if you botch the Construction.

The coolest thing about a Partscaster is also its greatest drawback: YOU’RE putting it together! How it turns out is totally on you, bud.

Still, if you’ve got the time and a little money… maybe you’ve even got some old guitar parts lying around that are doing absolutely nothing except gathering dust…

… then you might as well go for it! Even if you mess up, who cares?! It won’t be a big loss if you haven’t spent much.

And you’ve learned something along the way about guitar construction. It’s always good to know more about your axe, and one day, who knows… you can always try again.

Stick Your Neck Out!

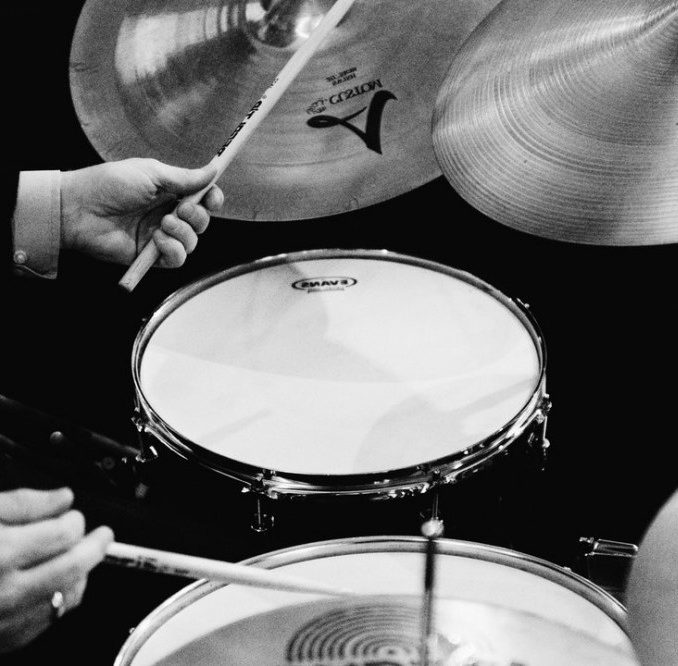

One of the simplest ways to create a Partscaster is to swap the neck out on one of your guitars.

I played a brand new Telecaster this past year, and did a review on it in THIS ARTICLE. I absolutely hated the neck. It was HUUUGE! Like a baseball bat.

But it sounded good. So, if I had kept that guitar (I didn’t), one thing was certain: I would have swapped the neck out on it as soon as possible.

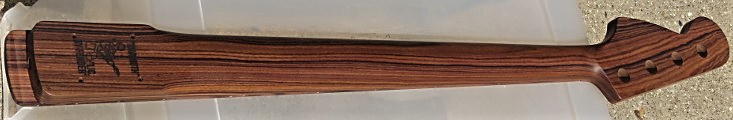

I’m partial to Stratocaster necks, since I’ve played them for years. A friend of mine here in town, for example, has a beautiful Pau Ferro Strat neck for sale that would be just the ticket.

If you do this though, just make sure you check the neck measurements to make sure you’re getting the right size for your guitar body. There are different styles, and they won’t all fit together.

Research first. Then pull the trigger. You’ll be a much happier shredder. 😉

You Gotta Be KIT-in’ Me?!

If you’ve got a little time on your hands, but you still have zero carpentry skills, you might want to consider buying a guitar kit.

With this approach, you are sent all the pieces of a guitar but none are put together. Usually, none of them have been painted or glossed at all either.

So, it’ll take a lot of work on your part before that finished axe is ready to be played. But, if you’re up for the challenge, “rolling your own” can bring a lot of satisfaction. Every time you strap that “job well done” on it’ll bring quite a smile to your face.

And if you do it right… to the faces of OTHERS too. 😉

One added benefit of putting the whole shebang together is that it teaches you about guitar construction in a way no Internet post ever could. But it’s beneficial not only from the standpoint of education…

Just think how, in the future, should you ever want to add, subtract, repair or swap out anything on your axe, how much more well-informed you’ll be on how to do it?!

And if you’re well-informed, you’ll have more confidence. And with more knowledge and confidence… comes great skill!

So, chances are, your final product will not only work, it’ll be bangin’! That’s worth it’s weight in amps, right there!! 😉

The Ultimate Itch Solution

If you’re really itching to build your own guitar, and want to go the WHOLE way…

… well, you’re a lot braver than me! But it can be done; you can build a whole guitar from scratch. And from any wood you want. Dining room table?? Why not?! Just clear it with the REST of your family first. 😉

This will necessitate you having some serious carpentry skills, not to mention some serious carpentry tools!

Shaping the contours of the guitar body, for example, is a mean feat, and extremely difficult to pull off for the inexperienced hand.

Still, if that dream is rousing up inside you and you believe you have the wherewithal to accomplish it, GO for it!

Don’t think you have to do it alone either. Take a construction cue from Brian May, rockin’ axe genius for Queen: he built his legendary Red Special guitar with his Dad!

Brian was only 16 when they started the build together. It’s not hard to imagine him thinking “Gee, I could probably use a little help with this.”

Because of that, for the last four decades Brian has been able to play a completely “personalized to his own tastes” guitar which has burned its tone into our collective psyche via Queen’s soundtrack to our lives.

“Bohemian Rhapsody”, anyone?!

Probably best of all, the memory of him and his late father building it together must be precious to him. Every time he plays it he must think, “Miss you, Dad.”

That rocks. 🙂

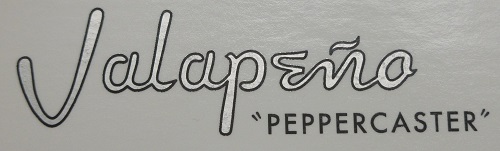

Write on Your Head!!

One of the most fun parts of building your own guitar is applying your own custom headstock insignia to the finished product.

There are some who just slap an authentic Fender logo on the headstock when they finish a build. To me, that’s missing out on a great opportunity for personal expression, not to mention creating possible confusion in the future about whether the guitar is truly a factory Fender instrument or not.

So get creative! It’s an awesome confidence booster to get on stage and rock with a guitar that has your name on it, or your signature, or your favorite catch-phrase.

You can use your favorite font. Draw up your own personalized graphic. Heck, draw a CARTOON of yourself and slap it on the darn thing! Your brain-sky’s the limit. And your fans?? They LOVE that kind of personal touch!

It’s pretty simple to do: just get decal paper at a hobby store, or online. Then draw something up on the decal paper, and print it out on an ink jet printer.

It’ll have to have a little finishing surface spray on top too, but you’ll learn all about what you coat guitars with when you do your build.

If you’re not a graphics kind of person, let’s make it even simpler for you: check out THIS PARTSCASTER DECAL FORUM for great type & print ideas. Or order some ready-to-go decals at THIS SITE by just telling ’em what you want your ‘stock to say!

Easy-peasy, trem’ bar squeezy!!

Parts to Play

Okay, so… where do ya go to GET all this stuff you need to build your own Partscaster??

Here are the best places I’ve found for lining up all the “right stuff”. Just click the names to link to their websites. Many online reviewers who have built some cool-looking electrics give these providers a big thumbs-up, so… get exploring!!

Also, for some great pictures of players who’ve completed a Partscaster using these stores, and are showing off the results, GO HERE. It’ll give you better direction as to what body types you want to pursue if nothing else.

Parting with Your Parts

Time to get real for a moment about a sad-but-true fact concerning the guitar you will spend days, weeks… perhaps even months constructing: if you wanna sell it later, prepare yourself… you’re not gonna get much.

Resale on a Partscaster is much harder than a typical instrument. you’ve gotta know going into your great guitar adventure that you might not get back all the money you put into it. In fact, you might find yourself stuck in “Lowballers Alley” for quite some time.

It makes sense in a way though. People are going to be quite skeptical about your luthier expertise if that’s not what you do for a living. In the back of their minds they’ll be thinking, “But what if he got something wrong??”

Why? Simple human suspicion. Their doubts aren’t that far-fetched either. There are a LOT of really poorly-made Partscasters out there!

But if you build a “self-expressin’ Strat” simply because you want to learn a lot about guitar construction, have the time & money to do it without needing recompense, and are eager to jam on an instrument that’s uniquely YOU, then the fact that you won’t get much for resale isn’t an issue, right?

It’s about the journey, not the destination. 😉

How do They Stack Up??

Our fellow shredder Darrell Braun did a GREAT stock guitar vs. Partscaster guitar shootout that I just love. Check out this video he did and then come back and tell us which one YOU thought wins the day.

To me, it was obvious…

Why I’m a Fan!

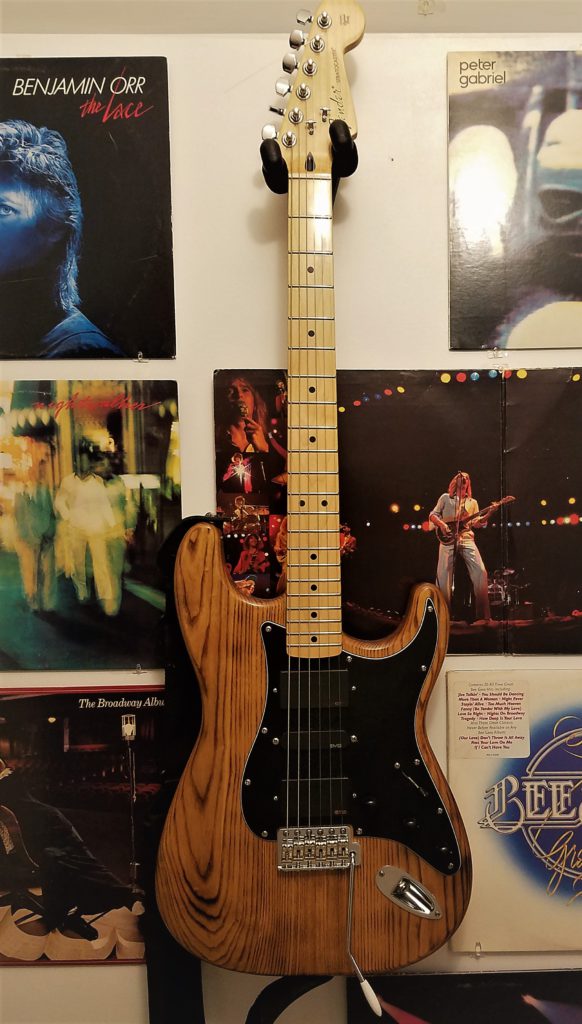

Finally, I’d like to introduce you to a wonderful Partscaster that my friend John Alexander made, and that I purchased from him. Meet… “Verbrannt“!!

This beautiful guitar has a body made of “burned Ash wood“. It’s the product of a technique where you put the wood in a fire for a short time, then finish it with Tru-oil and a bit of sanding.

The fire causes the grain to darken, bringing out a kind of “Tiger Stripe” look. Cool look, right?!

Here’s what the body looked like when John first got it new from Rosser Guitars (linked above):

Not nearly as dramatic without the Tiger striping!

The neck, bridge & neck plate John bought new off EBay.

John put EMG pickups that he already had in this guitar, and coil tapped the bridge & neck pickups to give me a lot more diversity of tone. I can get so many sounds out of this thing, it’s truly inspiring.

It’s also an “active pickup” configuration, which is what I prefer at times for certain types of playing.

I had a Strat very similiar to this that I played for years. It was stolen in 1995. Yea. Totally sucks. Read my tribute to it in THIS POST.

That sting of stolen loss is lessened now that I have a guitar that’s so similiar, though. Feels good to be back in the EMG Strat saddle again!

I named this axe “Verbrannt” because that’s the German word for “burned”. I was so impressed by how simply putting wood into fire and then oiling it could produce such a lovely finish. It really stands out among my other guitars!

Now you can see why I’m a fan of Partscasters. Brian May’s story already had me interested, but now that I see how a guitar can be made to one’s exact specifications and turn out so well…

… I’m a believer!! Lol

Greater Than

A patiently-constructed Partscaster truly is greater than the sum of its parts. The sounds, looks and feel you can get when you “go your own way”, to quote Fleetwood Mac, is quite exceptional and can run the gamut from outlandish to pro quality “wowism”!

Ready to do it? Already have?? Gonna research a little more to get perfectly focused on your ‘dream axe’??? Drop us a line in the Comments and tell us. Let us know too if you need any further help in this area, or how our look today furthered your quest for tone.

We can never know too much about the instruments we play. It gives us just that much more intuition about how to eke the most out of our beloved music-makers. So building one ourselves?? That’s like a guitar Ph.D., my friends.

My graduation hat’s off to you. 😉

Now, go… make… sounds!!

Teaj